The type of yarn plays a crucial role in defining the brand and becomes a deciding factor for product identification and differentiation. Most brands choose primary colours to represent their brand and develop brand association among their consumers. However, the quality of dyed yarns highly depends on the process and determines the longevity, durability and reliability of the final product. Also, if the yarn is used explicitly for residential or textile applications, comfort and appearance are of utmost priority. Here, we will discuss the two kinds of dyed yarns – packaged dyed vs solution dyed yarns – and explore their applications so that you can choose the right type of yarn for your industry.

Packaged Dyed Yarns and Solution Dyed Yarns: The Main Difference

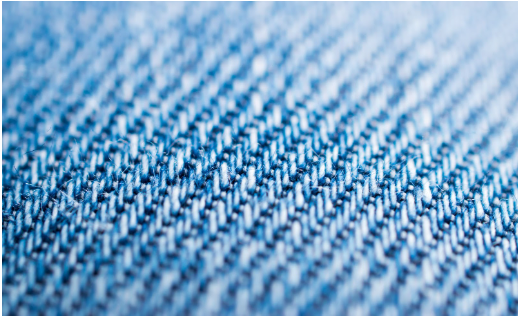

Packaged dyed yarns use matured technology wherein the yarns are wounded on perforated cores. The tube package is consistently perforated so that dye flows through the yarn package. This process continues until it has come to complete exhaustion, after which the coloured package is removed. The wounded package generally consists of polyester, cotton, acrylic or viscose, weighing from 500 g to 6 kg. Packaged dyed yarns are also known as cop, cheese, cone and bobbin dyeing.

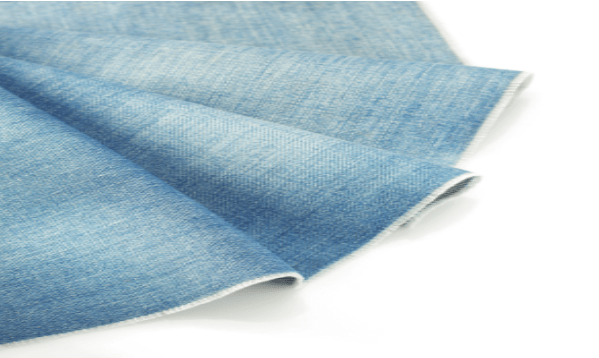

Solution dyed yarns use a method where the colour dye is included in the liquid stage before cooling. Then, it is spun into yarn. The colour is incorporated during the production of fibres. This technique reduces energy and water use in the process, which is why it is also labelled as sustainable. It usually demands enormous lot sizes of up to 4,500 kg.

Packaged Dyed Yarns: Advantages and Disadvantages

Advantages of packaged dyed yarns:

- Enables more flexibility in terms of colour development

- Provides customised colour options due to the small size lot

- Maintains colour consistency throughout the yarn

- Enables more flexibility in terms of quantity and shade

- Provides better hand feel over solution dyed yarns

Disadvantages of packaged dyed yarns

- Works to be a long and time-consuming process

- Uses higher volumes of water and energy

- Colour fastness is low in some shades as compared to solution dyed yarns

Solution Dyed Yarns: Advantages and Disadvantages

Advantages of solution dyed yarns

- Has high resistance to UV, fade and shade changes

- Saves water and energy during the dyeing process

- Maintains uniformity in colour

- Provides lower shade variation compared to package dyed yarn

- Works to be more cost-effective

Disadvantages of solution dyed yarns

- Requires large lot sizes of 4,500 kg or more

- Provides fewer colour choices without a custom colour option

- Uses only primary colours in dyes

Choosing the right kind of yarn

Before choosing a yarn, take a larger view of the final product and its applications. It will help you choose the right kind of yarn for your industry and product.

AYM Syntex, the leading manufacturer of yarns, provides high-quality packaged dyed yarns. Our yarns are used explicitly for dress materials, sarees, suiting, shirting, narrow width tapes and hosiery. The top-notch technologies we utilise in our yarn-manufacturing process enable us to offer the best-in-class yarns to the manufacturers and end-users. We are also one of the largest exporters of high-quality packaged dyed yarns. Connect with us to level up the quality of your products.

Also Read:

i.Difference Between Polyester Yarn and Nylon Yarn

ii.Differences between Partially Oriented Yarn (POY) vs Fully Drawn Yarn (FDY)